tel. 33 822 31 51

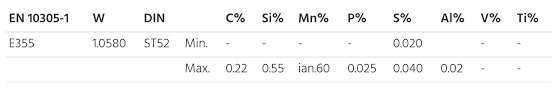

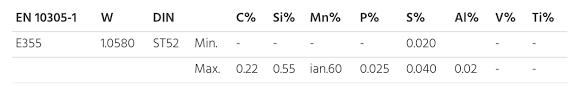

*CEV calculated with the formula:

*Some diameters may be subject to a minimum quantity requested

**Lengths may vary depending on the Chroming process used

***Other diameters, lengths/cut lengths can be provided at premium price